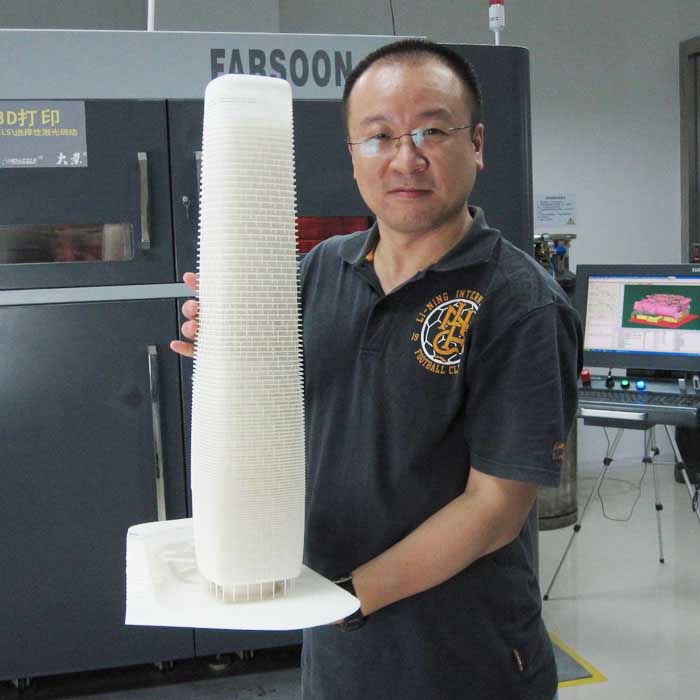

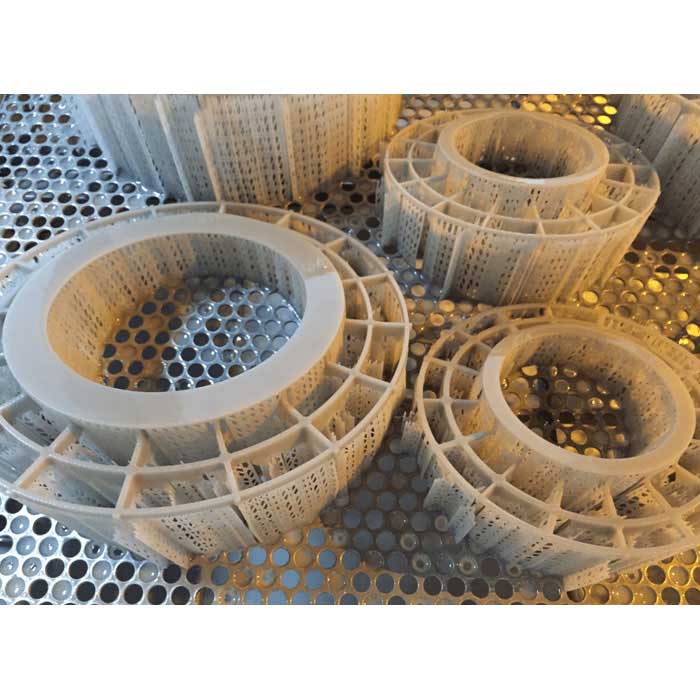

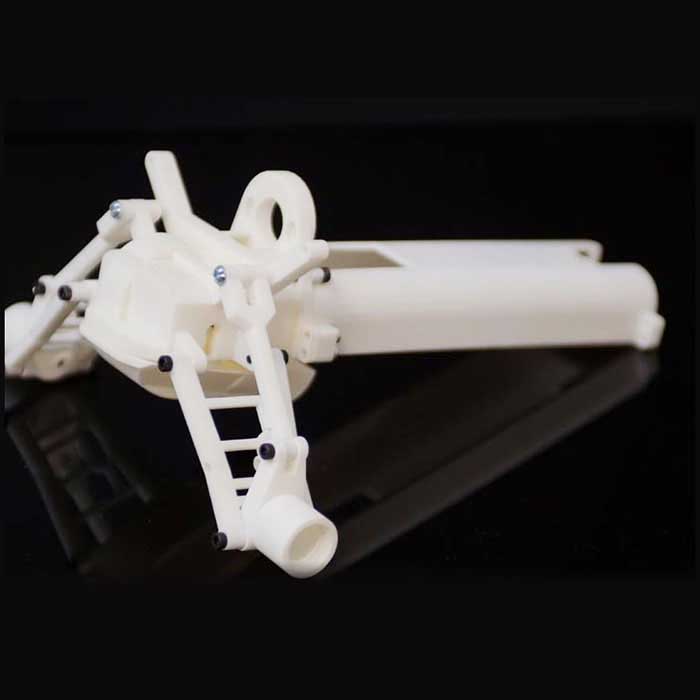

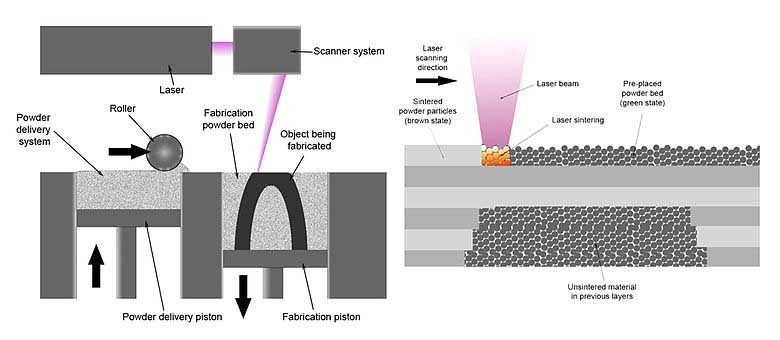

Elective laser sintering (SLS) is an additive manufacturing (AM) technique that uses a laser as the power source to sinter powdered material (typically Nylon), aiming the laser automatically at points in space defined by a 3D model, binding the material together to create a solid structure.

Compared with other methods of additive manufacturing, SLS can produce parts from a relatively wide range of commercially available powder materials. These include polymers such as nylon (neat, glass-filled, or with other fillers) or polystyrene, metals including steel, titanium, alloy mixtures, and composites and green sand.

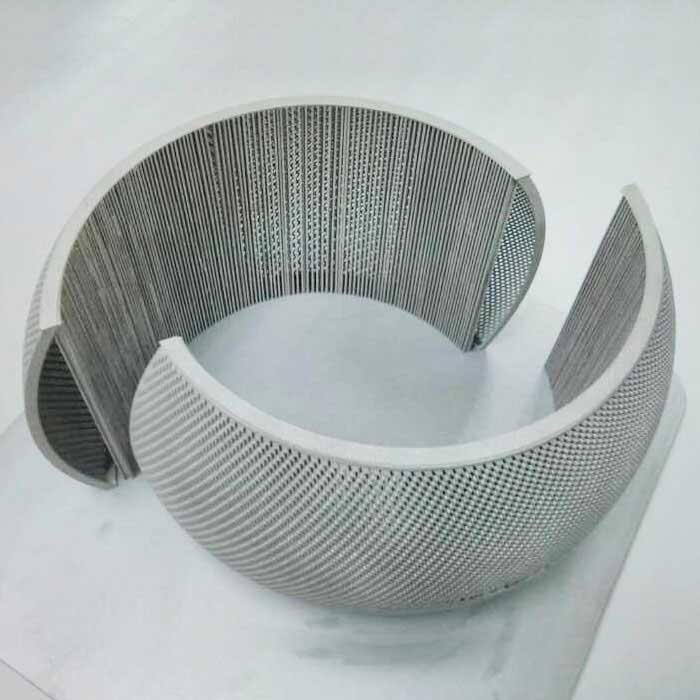

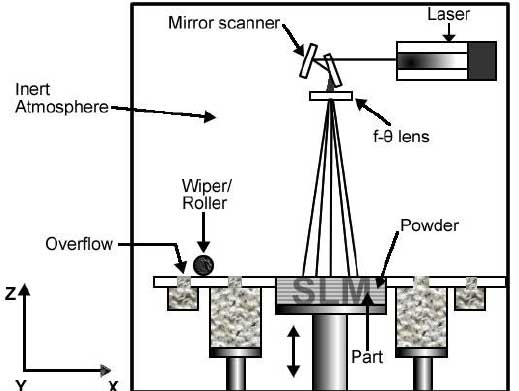

Selective laser melting is an additive manufacturing process that uses 3D CAD data as a digital information source and energy in the form of a high-power laser beam, to create three-dimensional metal parts by fusing fine metal powders together.

The types of materials that can be processed include stainless steel, tool steel, cobalt chrome, titanium and aluminium.

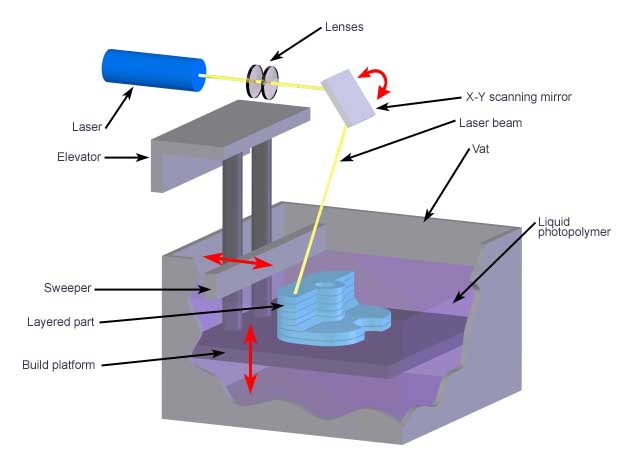

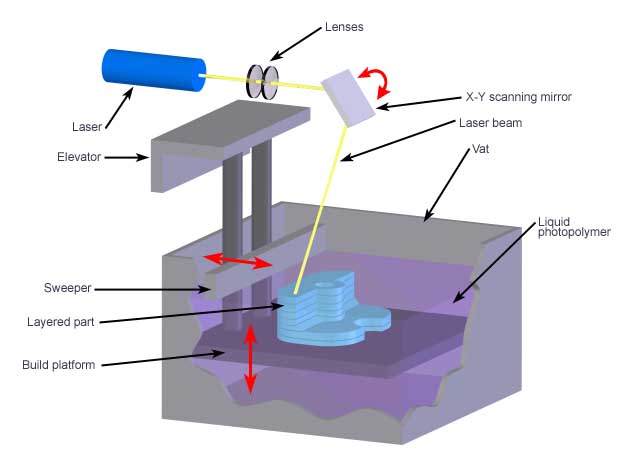

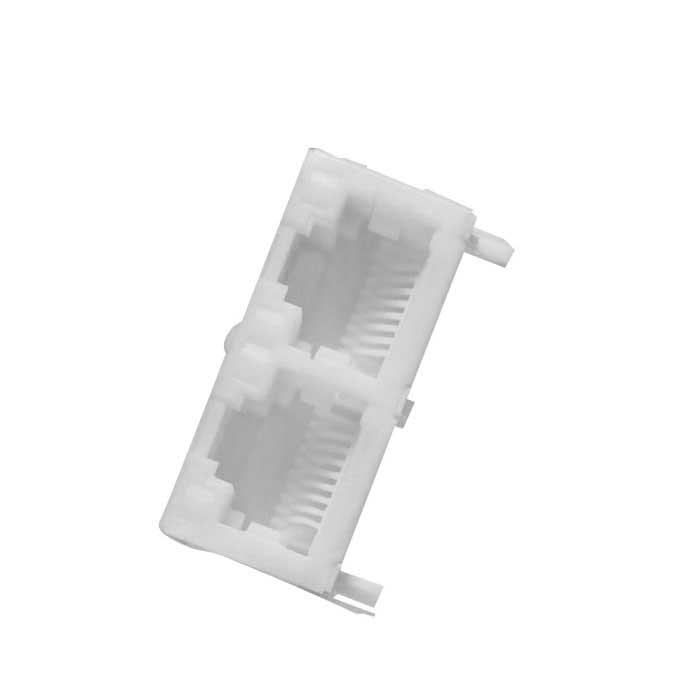

Stereolithography is a form of 3-D printing technology used for creating models, prototypes, patterns, and production parts in a layer by layer fashion using photopolymerization, a process by which light causes chains of molecules to link together, forming polymers. Those polymers then make up the body of a three-dimensional solid.

Liquid, Resin